WHY SHOULD YOU CONSIDER DIGITALIZATION OF COMPRESSED AIR SYSTEMS ?

Do You Know that Compressed Air Systems Are Highly In-Efficient?

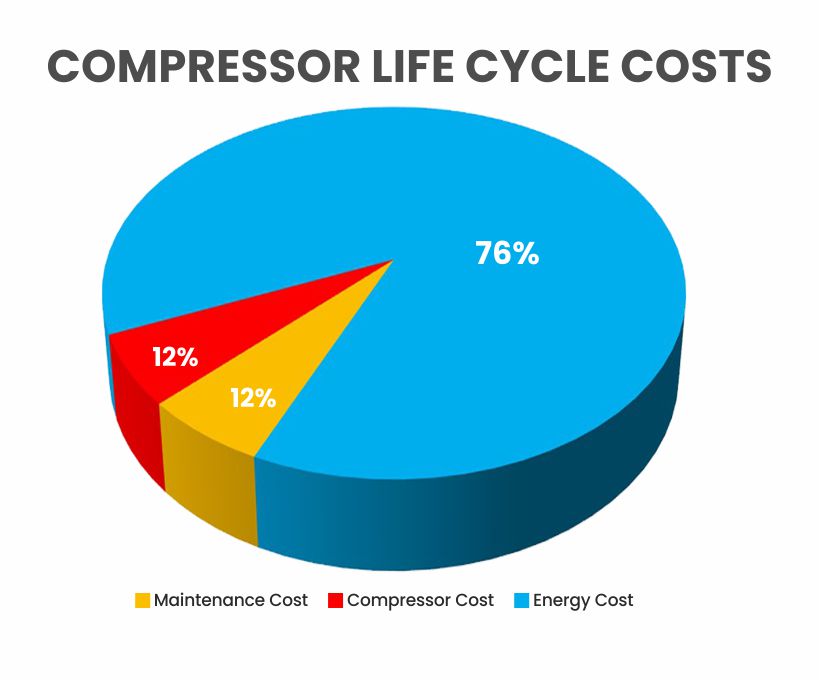

Compressed Air Systems are very widely used in almost all manufacturing industries and are usually the Single Highest Source of Energy Consumption in a Plant. Through Out the Compressor’s Life Time More than 76 % of the Costs are spent towards its Energy with the Capital and Maintenance Cost only at 12 % Each.

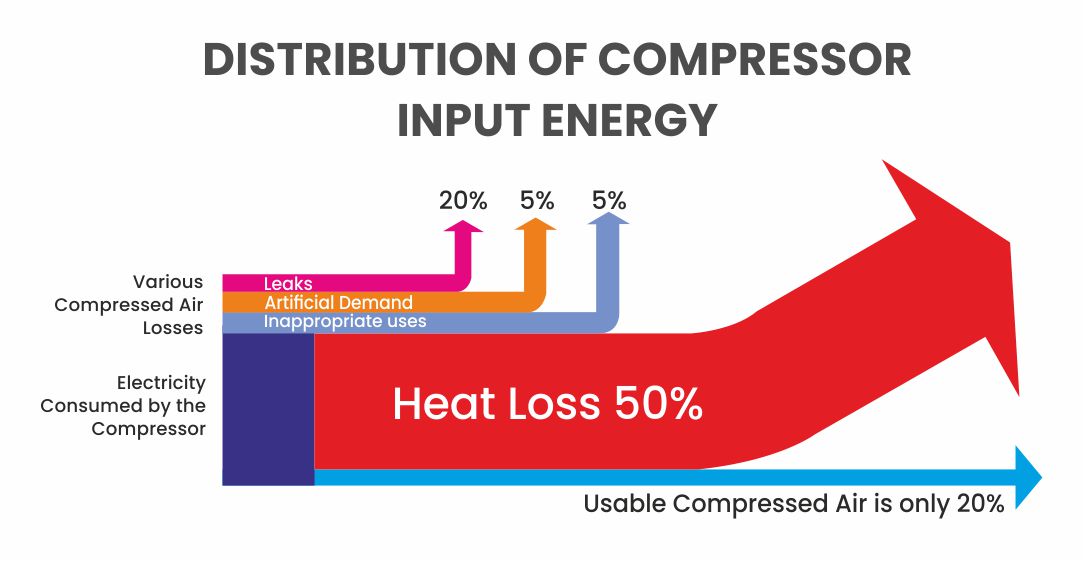

Further more Compressed Air Systems consume High Energy due to various losses happening during its Generation, Distribution and Consumption. Given below is a simple chart explaining common losses happening across the Compressed Air System.

A Compressor Loses Almost 50% of its Input Electrical Energy in the Form of Heat. Leaks are another Common Form of Losses in Industrial Compressed Air Systems Usually Accounting for Upto 20 % of the Compressed Air System Capacity. Unregulated End Points increase the Air Consumption and are hence rightly termed as Artificial Demand. Artificial Demands Exists between 5 – 10 % in any given Plant. Losses resulting due to Usage of Compressed Air in applications which can operate with alternate sources of Energy are termed as In-Appropriate Uses and they usually range between 5 – 10 % of the Overall Energy Loss in the System.

Common Pain Points in Operating a Compressed Air System

- High Energy Costs

- Re-occurrence Of Leakages

- Poor Air Quality

- Higher Cost Of Ownership

- Production Interruption

- Frequent Break-down

- High Maintenance Costs

Compressed Air Systems Normally Experience

- Excessive Energy Utilization

- Non Productive Efforts

- Asset Depreciations

- High & Repeated Efforts

- Confusion – Where to Start?

Compressed Air Monitoring is Important, Because

- Improves Your Compressed Air System Efficiency

- Saves Energy and Costs

- Reduces System Maintenance and Hence Lowers Labour Costs

- Reduces Operating Costs

- Keeps You Informed About Your System Dynamics

- Identifies changes in system performance

- Alerts You During Increased Leakage or Consumption.

- Tracks Your Peak and Average Demand

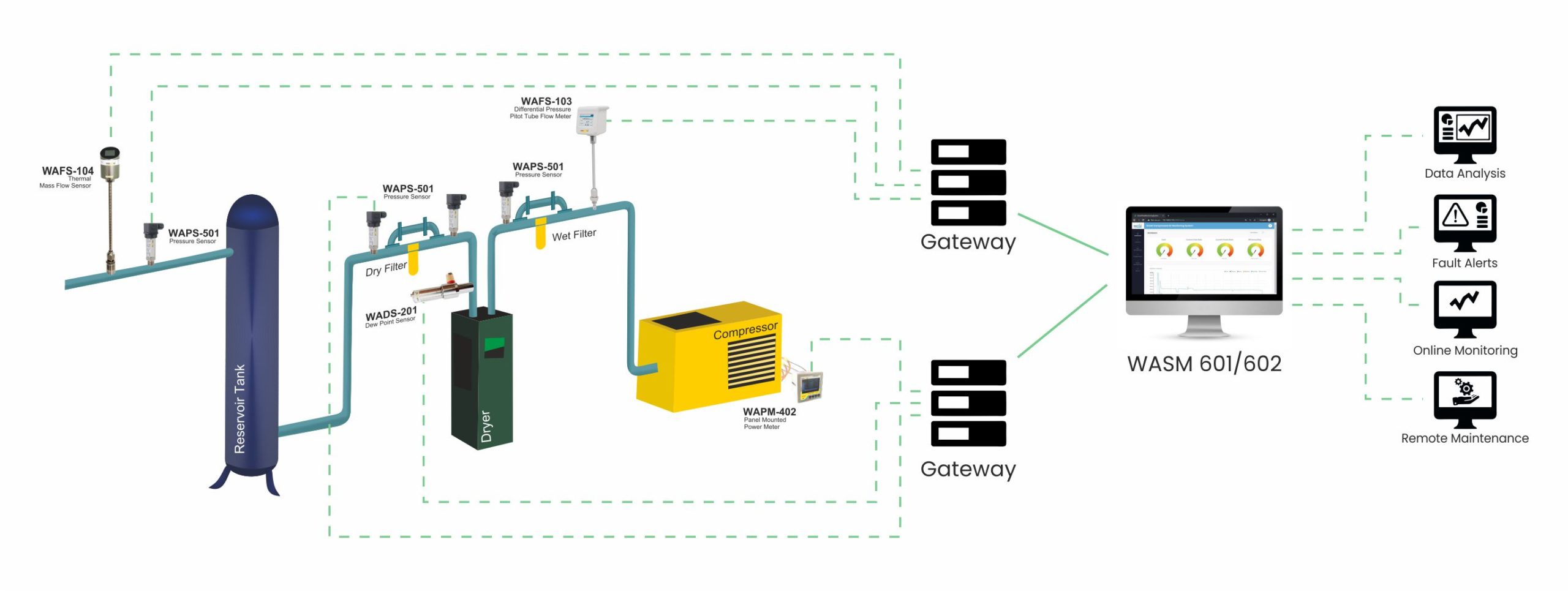

OUR SMART MONITORING ARCHITECTURE

Benefits of Compressed Air System Digitalization

- Helps You Validate your Compressor, Dryer and Allied Equipments Performance

- Simplifies Maintenance

- Eases Trouble Shooting

- Saves Energy

- Improves Cost Savings

- Sustains Savings & Improvements Realised

The Bigger Your Compressed Air System, the Lesser Your Return on Investments Period. For a Typical Compressed Air System with A Capacity of 1000 CFM the Approximate Investment for Digitalization of the Entire Compressed Air System would be in the Range of Rs 15 lakhs.

Regional Office

# 12 Sri Venkatalakshmi Nagar

Singanallur, Coimbatore – 641005

India