Understanding Compressed Air Audits – What Can They Do for You?

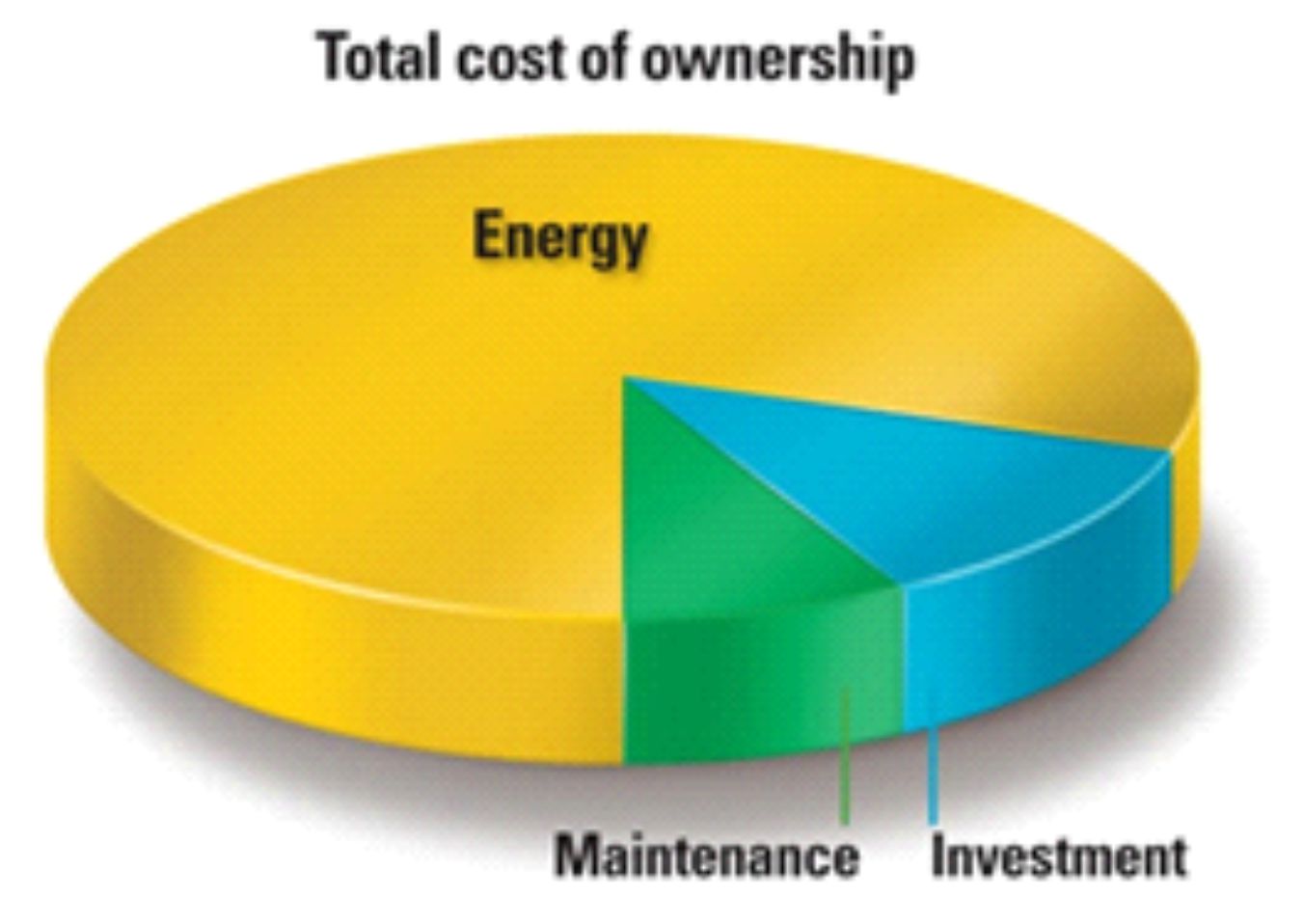

Manufacturing facilities spend around 40% of their total energy costs on compressed air alone, making an efficient compressed air system critical for maintaining a healthy bottom line. Unfortunately, not all systems operate in the most efficient manner possible, and we see it every day – compressors not appropriately sized, outdated technology, air leaks, pressure drops – the list can go on and on.

Increasing energy costs is a widespread concern. The Energy has estimated that over 50% of industrial air compressors are not running efficiently, resulting in 20% of energy waste annually. The good news is that manufacturers included in this study that dedicated resources to lowering energy costs were able to save upwards of 15% annually with a payback of fewer than two years.

So, how can you ensure an efficient compressed air system at your plant?

Compressed Air Audit – Uncover the Health of Your System

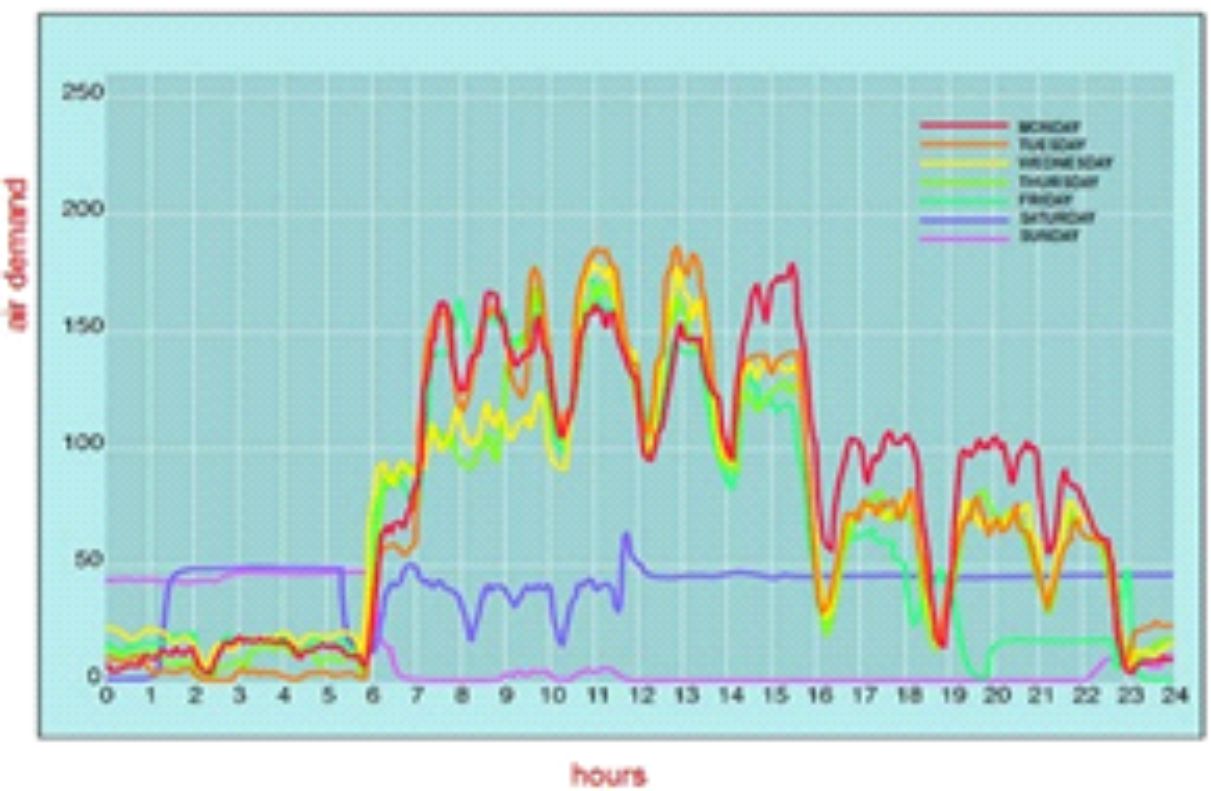

A full-scale compressed air audit is a much more thorough, in-depth look at your compressor system. An audit won’t disrupt your facility’s operations; rather, it’s performed while the equipment is running. Air audits typically utilize data loggers to measure power (kW), pressure, flow, dewpoint, temperatures, etc., and are designed to provide a very detailed look at the compressed air utilization within a given system. To gather needed information, data loggers are attached to the air compressor and throughout the compressed air network for a minimum of 7-14 days in order to observe and record system dynamics throughout the normal work week, as well as the weekends.

Results of such audits can provide a good understanding of the actual compressed air usage over a certain time period, identify any compressed air anomalies and help identify ways to improve the overall efficiency of the system. In addition, multiple options are typically available for each audit; they can include air quality audits, maintenance reviews, air leak detection and control, and monitoring and control programs.

There are several levels of compressed air audits that can be performed – walk-through assessment, system assessment, or a full system audit.

Walk-through Evaluation

This process typically takes ½ to 2 days and includes an overview of the plants compressed air system including an analysis of the distribution system to check for leaks, pressure drops, and compressor sizing issues. The compressed air system will be mapped out, and a report of findings and solutions will be proposed.

System Assessment

For a more thorough review, a system assessment is available that includes a walk-through as well as readings collected to identify system dynamics. The compressed air system mapping will feature pressure and demand profiles. The findings of the report and the proposed solutions will be provided at the conclusion of the assessment.

Full System Audit

The system audit is the most comprehensive review and takes around 3 to 10 days with little to no impact on current running procedures. Full compressed air system audits include:

– Energy usage data logging – logs the energy the air compressors are consuming.

– Air measurement – identifies a factory’s true compressed air demand and operating schedule.

– Air leak detection & control – identify how much air is being lost due to leaks.

– Air quality – measures the number of particulates in the air system such as water and oil.

– Maintenance review – assesses the effectiveness of the current maintenance plan.

– Monitoring & control program – makes recommendations to maintain optimum efficiency.

Manufacturing Benefits of an Air Audit

Manufacturers using compressed air regardless of the industry – food and beverage, automotive, textile, power, electronics, plastics to name a few will often find that a compressed air audit will pay for itself. Depending on the results of the audit, manufacturers can expect to see improvements in energy efficiency and system reliability and lower operating costs.

Regional Office

# 12 Sri Venkatalakshmi Nagar

Singanallur, Coimbatore – 641005

India