Importance of Compressed Air Flow Measurement

WHY SHOULD COMPRESSED AIR FLOW BE MONITORED ?

Compressed Air Systems are very dynamic and hence if not monitored will lead to huge mismatch between the Supply and Demand. Unbalanced Systems will result in,

- Over compensation of system pressures will increase artificial demand & increase of problems

- Higher Air Demand

- Higher Leak Rate

- Higher Repair Intervals and Costs

- Higher Energy Bills

- Higher Cost Per Product Produced

- Less Profits

SOLUTION – OUR WAFS 101 SENSORS :

WAFS 101 Is Specially Designed for Air and N2 Application Such as Compressed Air, Venting Air, Aeration, Process Protection N2 Combustion Air Etc. The WAFS 101 Is Mainly Used in Compressed Air Systems in the Industrial Environment.

PRINCIPLE OF MEASUREMENT:

WAFS 101 Series Thermal Mass Flow Meter Is Wise Air 4.0’s Latest Technologies Specially Designed for Air & N2 Application. It Has More Compact Design Which Means Smaller Enclosure and Thinner Insertion Tube Probe. WAFS – 101 Series Thermal Mass Flow Meter Measures the Gas Mass Flow Based on Thermal Diffusion Theory. It Has Two RTDs as its Sensors. One of Which Sense the Velocity of Gas Flow (RH) and Other One Will Detect the Temperature Shift of the Gas Flow (RMG). When the Two RTDs Are in Gas Flow, the RH Will Be Heated While the RMG Will Sense the Temperature Changing of the Gas Flow. More Heat Will Be Taken Away as the Velocity of the Flow Gas Flow Increases, so the Temperature RG Will Decline.

SALIENT FEATURES OF WAFS 101 ?

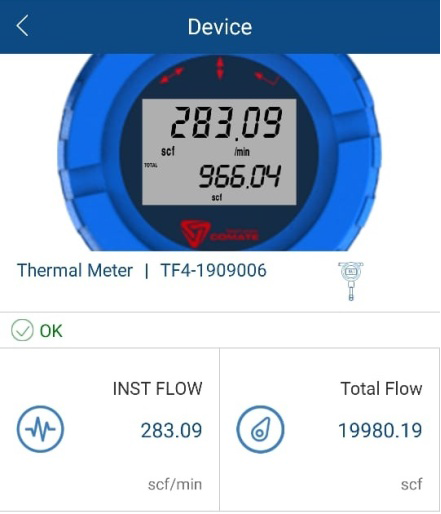

Measurement of Flow and Consumption in Dry air. Measure the Mass flow and Standard flow directly. Low Cost, Hence economical. Large LCD screen with Dual Line Display and 3 Setting Button. Optional Online Data logger Is Available. Maintenance and Self Diagnosis Option is Available online. It can be used in Pipes from DN25 –

DN500.

INSTALLING A WAFS FLOW SENSOR IS ABSOLUTELY IS A SMART DECISION:

WAFS 101 Can Be Used To Find the Air Consumption of Your Factory or Each Departments To Track the Daily Monitoring of Compressed Air Flow of Your Factory. Consistent Monitoring of Compressed Air Flow Can Reduce the Consumption of the Factory. Further High Air Consuming / Leaking Departments Can Be Identified and Brought Under Control With Flow Monitoring. Since WAFS 101 Is a Highly Accurate Portable Sensor, It Can Be Used in Multiple Locations for Temporary Measurements To Reduce the Capital Costs Constraint.

CASE STUDY ON THE BENEFITS OF WAFS 101:

An South India’s Leading Spinning Mill Highly known for its Quality Systems and Employee Orientation. As Early as in 2015, The Factory installed our Previous Generation Flow Sensors with Real Time Monitoring Software. From an Earlier Compressed Air Consumption of 850 CFM, the Factory was successful in reducing the demand to less than 650 CFM Post the Installation of the Sensor. Moreover Inspite of the Factory’s Expansion and Modernisation of the Machines, They Could Contain the Air Consumption by Strict and Regular Measurements at Various Departments. As Part of their Moderation Vision they have upgraded to our WAFS 101 Smart IIOT Flow Sensor in 2019 and

are currently Happy with the following Convenience,

- Savings of Nearly 20 % or Upto 140 CFM in Compressed Air Demand

- Easy Measurement with Our WiseAir Smart Mobile Application

- Easy Configurations & Factory Resets

- Deeper Understanding with Self Diagnosis Function

- Increased Portability for Measurements at Various Production Headers

- Low Cost of Installation

Regional Office

# 12 Sri Venkatalakshmi Nagar

Singanallur, Coimbatore – 641005

India